Fiberglass Rebar (GFRP): The Future of Corrosion-Free Reinforcement

A New Era in Construction Materials

Fiberglass rebar, technically known as Glass Fiber Reinforced Polymer (GFRP), is rapidly emerging as a durable and sustainable alternative to traditional steel reinforcement. As governments and construction firms worldwide aim to build longer-lasting, low-maintenance infrastructure, GFRP is stepping into the spotlight—particularly in the United States, where infrastructure investments are at an all-time high.

What Makes Fiberglass Rebar Different?

Unlike steel, fiberglass rebar doesn’t corrode, even in saltwater or chemical environments. Made from glass fibers embedded in a polymer resin, GFRP offers exceptional strength, lightweight handling, and a long lifespan.

| Property | Fiberglass (GFRP) Rebar | Steel Rebar |

|---|---|---|

| Corrosion Resistance | Excellent (non-metallic) | Poor in salt/chloride environments |

| Weight | 4–7× lighter | Heavy |

| Tensile Strength | 2–3× higher per weight | Moderate |

| Magnetic Conductivity | Non-magnetic, non-conductive | Conductive |

| Maintenance Needs | Very low | High |

| Fire Resistance | Moderate (requires coating) | Good |

GFRP’s unique non-corrosive nature is particularly useful for bridges, marine structures, chemical plants, and tunnels, where steel traditionally suffers from rust and chloride attack. Experts estimate that global corrosion-related concrete damage costs exceed $2.5 trillion annually, making GFRP a logical step forward in infrastructure renewal.

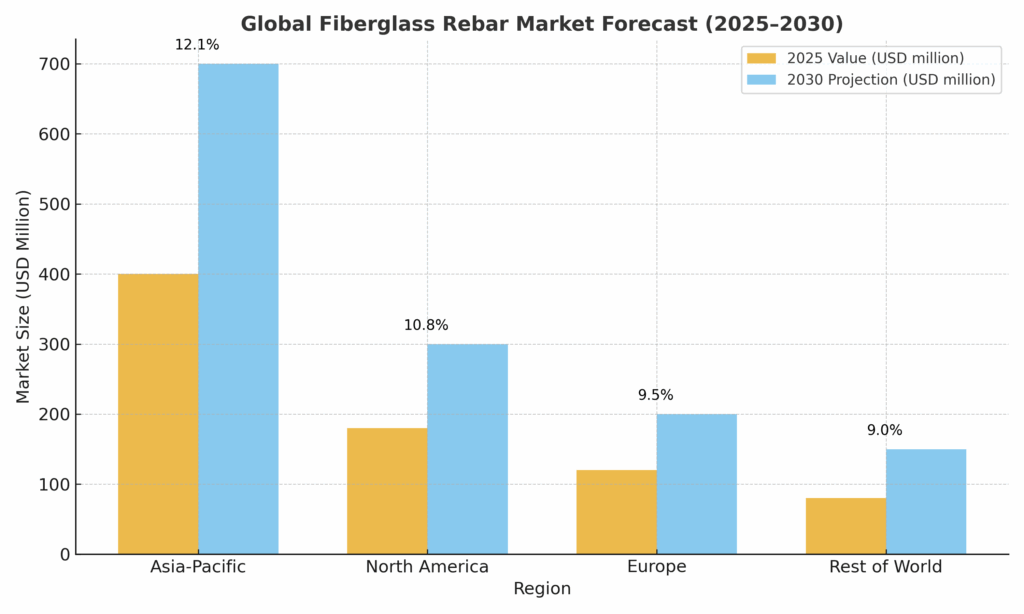

Global Market Trends

The global fiberglass rebar market is expanding at a remarkable pace. Analysts estimate that the market—currently valued between $0.7 and $0.8 billion—will reach $1.5 billion by 2030, growing at an average annual rate of 9–12%.

| Region | 2025 Value (USD) | 2030 Projection (USD) | Growth Rate (CAGR) |

|---|---|---|---|

| Asia-Pacific | $400 million | $700 million | 12.1% |

| North America | $180 million | $300 million | 10.8% |

| Europe | $120 million | $200 million | 9.5% |

| Rest of World | $80 million | $150 million | 9.0% |

In the U.S. alone, the market is projected to grow from $30.6 million in 2023 to $101.4 million by 2033. This growth aligns with America’s $1.8 trillion infrastructure investment plan, which emphasizes corrosion prevention and sustainable construction.

Manufacturing Innovations

The manufacturing process of fiberglass rebar, known as pultrusion, involves pulling glass fibers through resin and curing them through heated dies. Recent innovations are improving strength and bond performance.

One of the most advanced systems uses ultrasonic resin saturation and internal heating ovens to achieve uniform curing. This ensures the bar’s internal structure is free from microcracks and has stronger adhesion with concrete.

New Investments in the U.S.

In 2025, MST Rebar announced a $15.5 million factory in North Carolina, producing up to 75 miles of fiberglass rebar daily. This marks the company’s first U.S. plant and one of the largest GFRP production facilities in North America. MST’s “MST-BAR” product is already being used in the Alligator River Bridge project—one of the nation’s first major bridges reinforced with GFRP.

Codes, Standards, and Certifications

Fiberglass rebar has gained strong backing from global building codes and standards bodies. The most notable updates include:

- ACI 440.11-22 (2022): Official design code for GFRP in concrete.

- ASTM D7957 & D8505 (2023): Updated material standards including glass and basalt fibers.

- ICC-ES AC454: Defines product evaluation and acceptance criteria.

- CSA S807: Canadian standard for GFRP rebar design.

These standards ensure GFRP rebar meets strength, stiffness, and durability requirements across regions. However, some challenges—like limited fire resistance and lack of ductility—remain areas of active research and product innovation.

Real-World Projects Using GFRP

United States

- Alligator River Bridge, North Carolina: Using MST-BAR fiberglass rebar in decks, girders, and piers to extend service life in coastal environments.

- MD 5 Hilton Run Bridge, Maryland: First GFRP-reinforced bridge deck in the state, showcasing its corrosion resistance in harsh weather conditions.

International

- Champlain Bridge, Canada: Incorporated GFRP rebar in salt-exposed components to enhance longevity.

- Seaside Bridge, Netherlands: Used GFRP to combat corrosion from saltwater exposure.

- Swiss Tunnel Systems: Adopted fiberglass rock bolts for underground stability without rust.

Emerging Research and Smart Materials

Recent university research is developing thermoplastic FRP rebar—a new type of composite that can be bent on-site like steel but remains corrosion-proof and recyclable. These “field-bendable” thermoplastic bars could redefine how rebar is installed in the future.

Researchers are also experimenting with graphene-enhanced fiberglass to increase conductivity and overall tensile strength, paving the way for “smart concrete” systems capable of structural health monitoring.

Sustainability and Future Outlook

Beyond performance, fiberglass rebar also aligns with sustainability goals. Studies show that GFRP can reduce embodied carbon by up to 40% compared to steel reinforcement. With the global shift toward net-zero construction, this advantage is driving rapid adoption across both public and private projects.

As standards evolve and production costs fall, experts predict that fiberglass rebar will soon become a mainstream material in bridges, highways, and smart infrastructure. With its high strength, corrosion resistance, and eco-friendly profile, GFRP rebar is reshaping the future of construction—literally from the inside out.

References

- Owens Corning – “MATEENBAR and PINKBAR Fiberglass Rebar Joint Venture Announcement”

- MST Rebar – “North Carolina Factory Announcement, 2025”

- ACI Committee 440 – “Guide for the Design and Construction of GFRP Reinforced Concrete”

- ASTM International – “Standard D8505/D8505M-23 for FRP Bars”

- U.S. Department of Transportation – “Infrastructure Investment and Jobs Act Report”

- MDPI Journal of Building Engineering – “Comparative Study on Steel and GFRP Reinforcement”

- Composite-Tech – “Advanced Pultrusion Manufacturing Process”

- University of Maine – “Thermoplastic FRP Rebar Development Report”

- Global Market Insights – “FRP Rebar Market Forecast 2025–2030”

- Civil Engineering News – “Alligator River Bridge Project Details”

FAQ

What is fiberglass rebar (GFRP)?

Fiberglass rebar, also known as Glass Fiber Reinforced Polymer (GFRP), is a non-metallic reinforcement made of glass fibers embedded in a polymer resin. It’s designed to replace steel rebar in concrete structures where corrosion is a major concern.

How is fiberglass rebar different from steel rebar?

Unlike steel, fiberglass rebar does not rust or corrode. It’s up to seven times lighter, has 2–3 times higher tensile strength per weight, and is non-conductive—making it ideal for marine, chemical, and magnetic-sensitive structures.

Is fiberglass rebar stronger than steel?

Fiberglass rebar offers greater tensile strength per weight compared to steel, but it behaves differently—it doesn’t bend or yield before breaking. Engineers design GFRP-reinforced structures using higher safety factors to ensure durability and safety.

What are the main benefits of using fiberglass rebar?

Key benefits include:

Corrosion resistance in saltwater and chemical environments

Lightweight handling, reducing labor costs

High tensile strength and long lifespan

Non-magnetic and non-conductive properties

Lower maintenance and lifecycle costs

What are the limitations of fiberglass rebar?

Fiberglass rebar is more brittle than steel and loses strength at high temperatures. It also costs slightly more upfront, although the long-term savings from reduced maintenance often outweigh initial expenses.

Is fiberglass rebar approved by building codes?

Yes. It’s recognized by several standards including:

ACI 440.11-22 (U.S.) – design code for GFRP reinforced concrete

ASTM D7957 & D8505 (2023) – material specifications

ICC-ES AC454 – evaluation criteria for approval

CSA S807 (Canada) – design and testing standard for FRP rebar

Where is fiberglass rebar used today?

GFRP is increasingly used in:

Bridge decks and piers exposed to saltwater

Highway barriers and tunnels

Coastal and port infrastructure

Chemical plants and wastewater facilities

MRI rooms and electrical substations (due to non-conductivity)

What major projects use fiberglass rebar?

Some recent examples include:

Alligator River Bridge (North Carolina, USA)

MD 5 Hilton Run Bridge (Maryland, USA)

Champlain Bridge (Canada)

Seaside Bridge (Netherlands)

Swiss Tunnel Systems for corrosion-free rock bolts

How sustainable is fiberglass rebar?

Fiberglass rebar can reduce embodied carbon by up to 40% compared to steel. It requires less energy to produce, lasts longer, and supports net-zero construction goals by extending structure lifespans and reducing repair frequency.

What is the future of fiberglass rebar technology?

Researchers are developing thermoplastic and graphene-enhanced FRP rebars that are recyclable, bendable on-site, and even capable of sensing structural stress — paving the way for smart, sustainable infrastructure in the next decade.

Responses